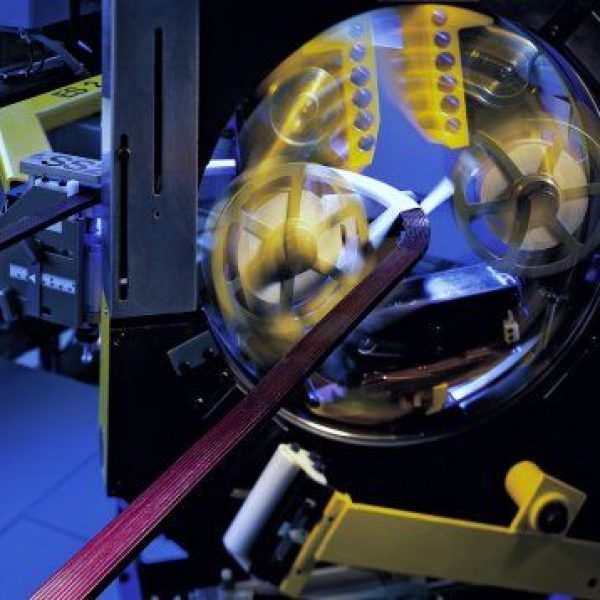

The largest East-European producer of ceramic tiles has started, with BCC support, a new functionalities in warehouse management in SAP system (SAP WM module). Managing product flow in the central sorting room is done without man’s participation.

Opoczno is one of the first companies in Poland to steer a fully automatic warehouse with the use of an ERP system. Physical movements of goods are carried out by robots. Such a solution was started in July.

The sorting room acts as a medium link between the tile production department and ready goods warehouse. From July fork lift trolleys operators have been replaced by robots that receive goods from production and based on SAP data pick appropriate batches for moving to the ready goods warehouse. Communication with SAP system is done through bar codes.

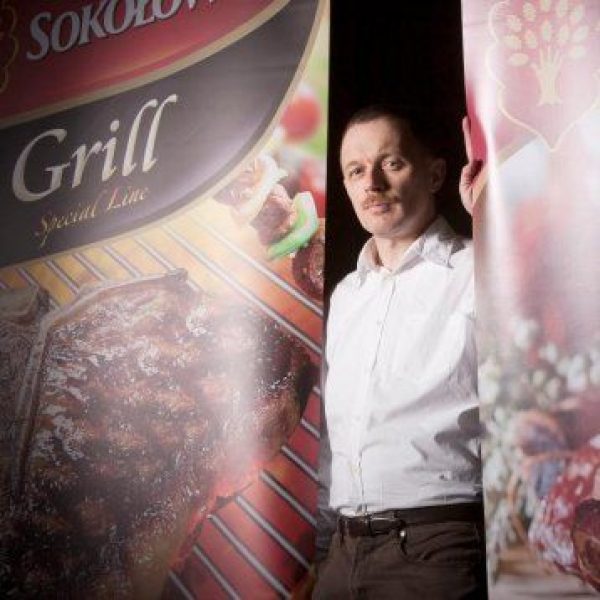

Piotr Żehaluk, logistics and planning director in Opoczno SA, estimates: ‘Making the sorting room fully automatic is a next step in improving logistic processes in our company. By using robots that communicate with SAP systems we improve goods flow management in the whole warehouse. As a result we reduce the total storage costs and make the delivery organization more efficient’.

Starting a fully automatic sorting room, managed by SAP system, is a further step in a BCC-carried implementation of advanced warehouse management solutions in Opoczno SA. Nowadays SAP system supports managing all three warehouses of the tiles manufacturer: besides the sorting room also the ready gods warehouse and commercial goods warehouse.