BCC is starting implementation of SPRINT Discrete Manufacturing in Kamax. It is the first contract for BCC to implement an industry preconfigured solution for middle-sized businesses in discrete manufacturing sector, offered within the global initiative mySAP All-in-One.

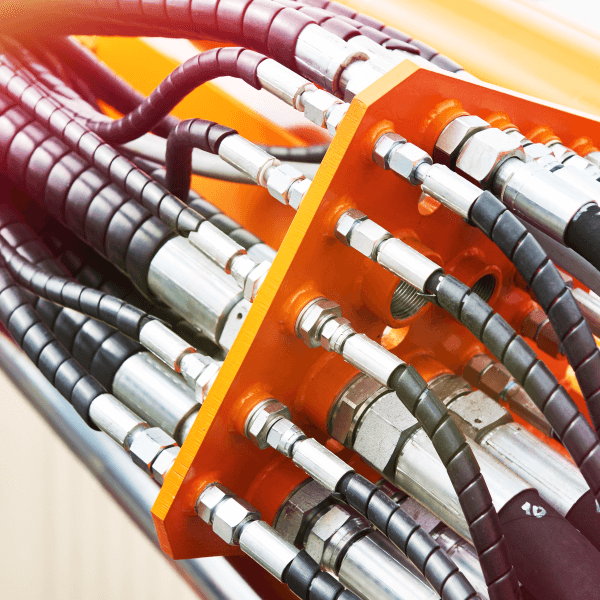

Kamax SA Mechanical Equipment Plant, seated in Kańczuga, specializes in manufacturing shock absorbers for trains and other equipment. Kamax clients include Polish PKP, Deutsche Bahn, railways in Russia, the Ukraine, China and others.

The project, started in April, includes the implementation of SAP functionality in the following areas: financial accounting, fixed assets, treasury, controlling, materials management, production planning, sales and distribution. The implementation contract also includes the delivery of license for SAP software.

SPRINT Discrete Manufacturing, created by BCC, is a solution based on mySAP ERP system, enabling quicker and cheaper SAP implementation in middles-sized businesses operating in discrete manufacturing sector. Its main advantage is ready-made (preconfigured) set of system functions that support business processes characteristic fort the industry. Using the package helps to reduce the time and costs of SAP implementation by 50% in comparison with the ‘classical’ SAP implementation, and limit the involvement of the client’s employees in implementation works.

‘Using the unique methods of implementation of SPRINT Discrete Manufacturing helps to reduce costs of SAP implementation. Moreover, preconfigured industrial solutions included into the package make it possible to take advantage of best practices in supply management and in production planning‘, said Witold Rymarz, project manager for Kamax.

‘Thanks to the great commitment of our partner companies, like BCC, we see that the global initiative mySAP All-in-One is more and more visible in the Polish market’, said Grzegorz Rogaliński, the chairman of SAP Polska. ‘Till now SAP Polska has already certified 11 industrial solutions of the type mySAP All-in-One, including as many as 3 created by BCC. SAP is the only global supplier of business solutions to create – by itself and with partners – such a wide offer of special packages tailored to the needs of particular industries. I am glad that Kamax has chosen SAP. That will strengthen the cooperation between SAP and BCC in discrete manufacturing sector’.

Kamax SA Mechanical Equipment Plant in Kańczuga produces, among others, shock absorbers and brass fittings to composite pipes. The company sells to Polish clients as well as abroad: to Russia, China, Germany, Sweden, Romania, Great Britain and the Ukraine. The company employs 450 people and controls a few companies in Poland; it also has affiliated companies in Ukraine, Russia and China. Kamax SA with its controlled and affiliated companies forms the Kamax group.